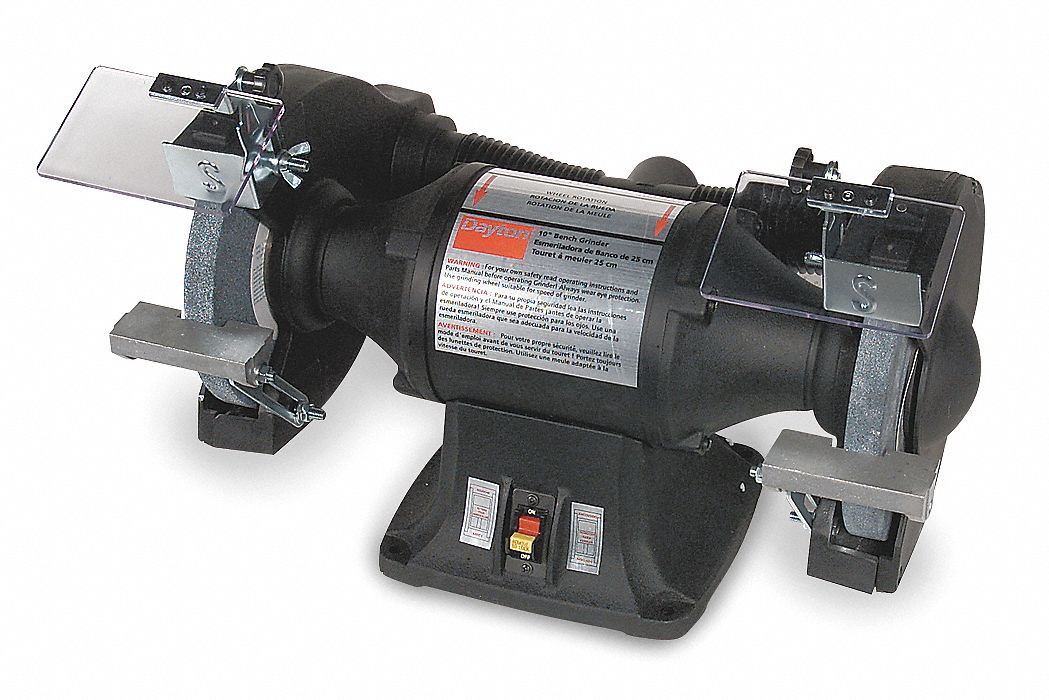

Bench grinders are a two wheel system that can íí sharpen tools that have become dull íí fix broken blades for steel fans to riding lawn equipmentíí polish and fix up small pieces of steel.

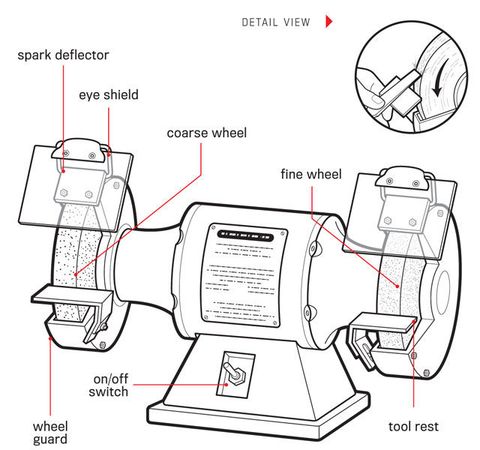

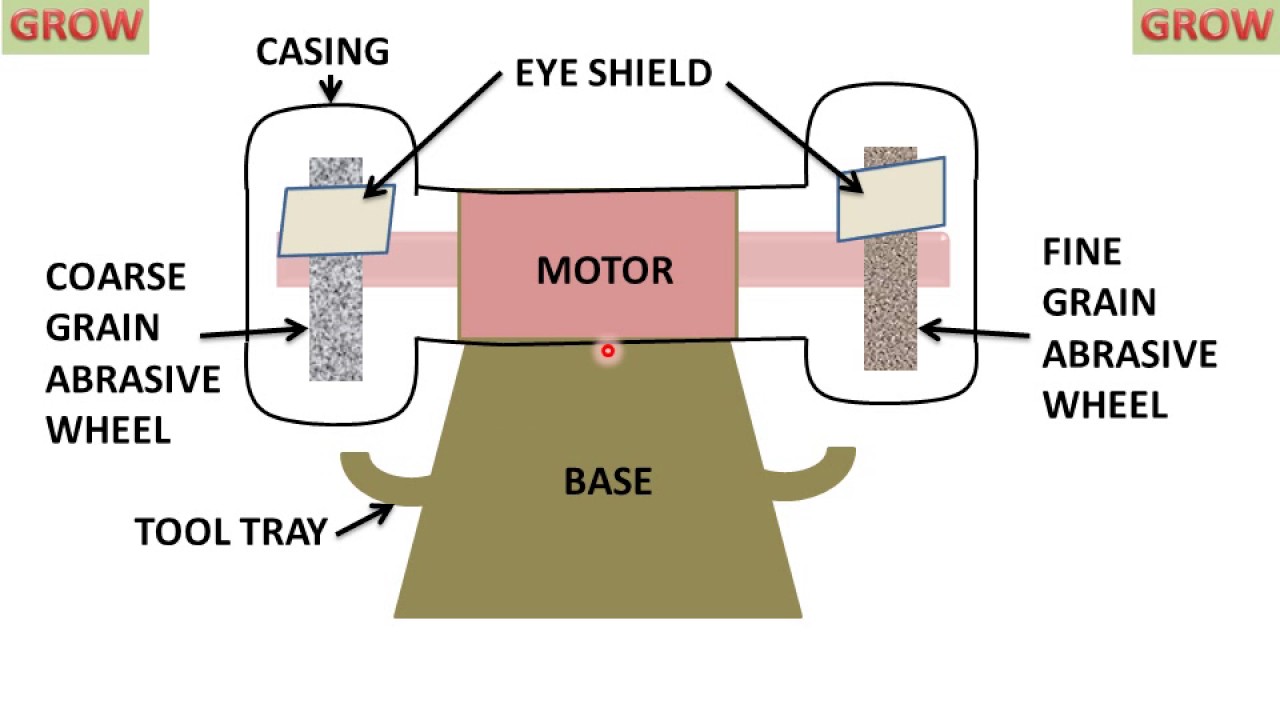

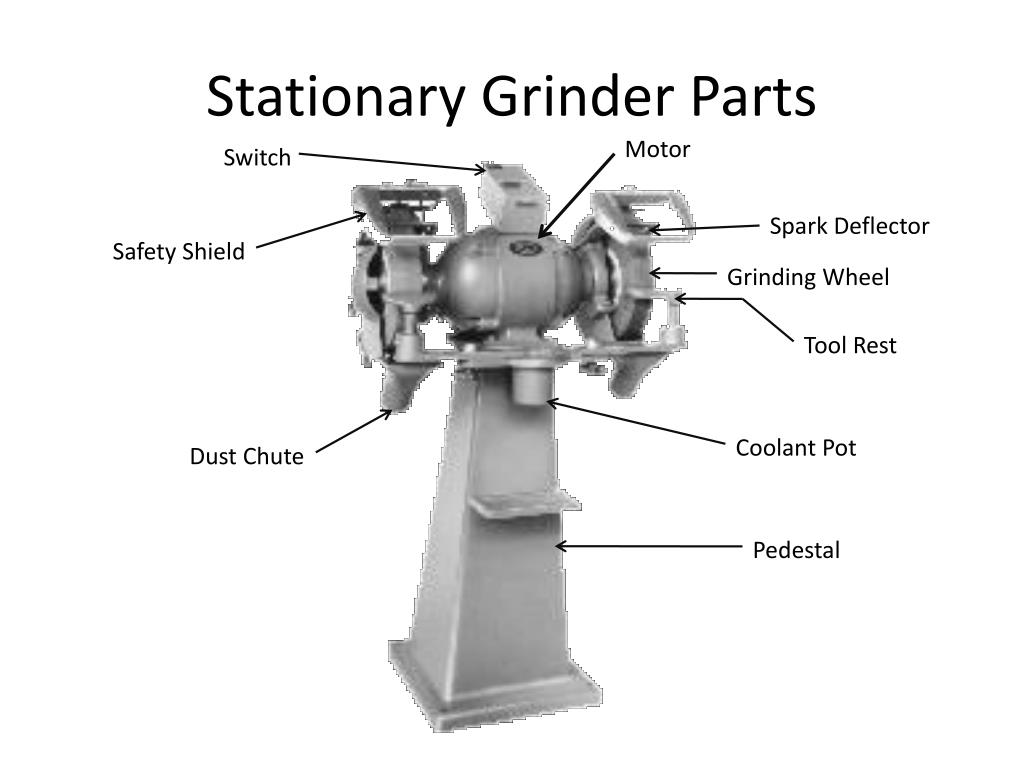

Bench grinder parts and functions.

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels.

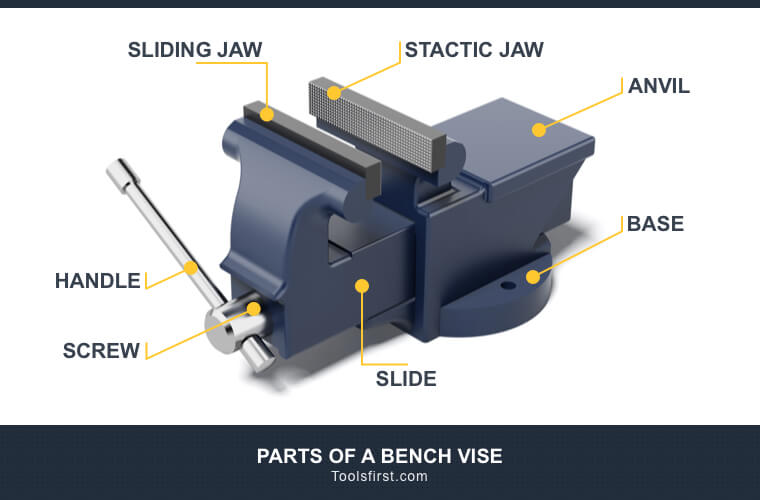

Please note the screw and the nut used to secure it to the unit are sold separately.

Bench grinders while effective are delicate pieces of equipment.

Parts of a grinding machine.

These types of grinders are commonly used to hand grind various cutting tools and perform other rough grinding.

A grinding machine consists of the following parts.

Most commonly it provides a tight seal for the connecting pieces inside the reel of your machine.

On two ends of themain body are two wheels.

Put simply a bench grinder will elevate the rest of your toolset providing sharpened blades edges and chisels as well as smoothing the edges of any objects you re working on.

A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal which may be bolted to the floor or may sit on rubber feet.

Depending on the bond and grade of the grinding wheel it may be used for sharpening cutting tools such as tool bits drill bits chisels and gouges.

Sure it s not going to be the fanciest tool in the shed nor the most expensive but that doesn t mean it s not the most important.

It also helps distribute the pressure in your tool.

This tool rest acts as a support for the material when the grinder is in use.

To replace it you will need a screwdriver.